Control Valve Repair

How Total Valve Systems Can Help Your Control Valve Repair Needs

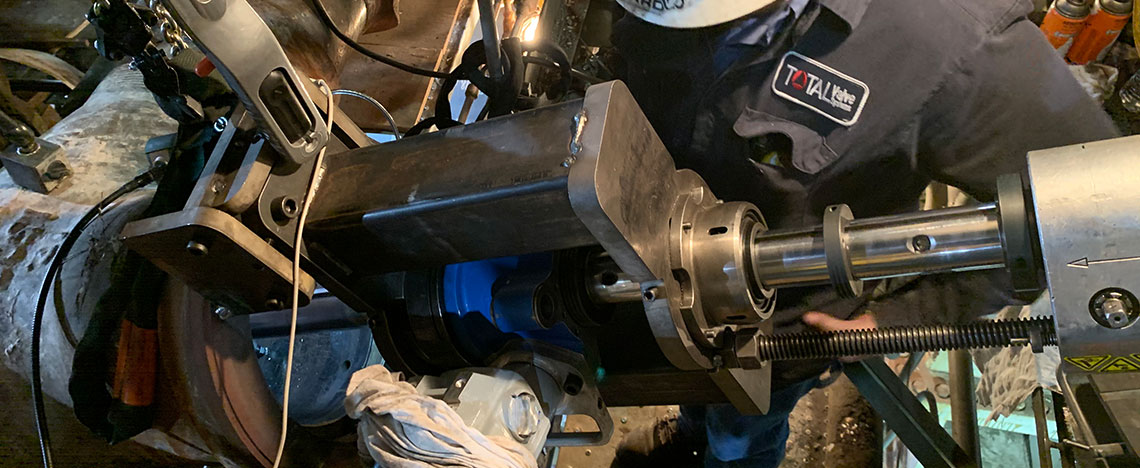

Total Valve offers both shop and field diagnostic and control valve repair services. By utilizing top notch diagnostic equipment, we can input your control valve’s configuration information, run baseline tests, then provide detailed documentation that will show the valve’s performance. This information can be used to determine if your control valve needs minor instrumentation calibrations or possibly a major overhaul.

After all repairs are made, including re-stroking the control valve and actuator assemblies and re-calibrating instrumentation, our valve techs will perform “as left” control valve diagnostics to document and then verify that the valve’s performance is within acceptable parameters.

Our Process

With our efficient and reliable process, most tests can be completed in 15 to 30 minutes. We provide test/repair reports at no additional cost. Full-page graphics can be resized or customized and are immediately available for print, preview, or export.

- Customization

- V-Ball

- Globe

- Butterfly

- Axial

- Rotary

image here

text here