Excess Flow Valves

Excess Flow valves are known by other names such as velocity check, emergency shutdown device, seismic valve, shutdown valve, surge preventer, earthquake valve, and line rupture valve. These valves are designed to close when a sudden flow surge occurs. Excess Flow valves are in-line valves through which pressurized gas or liquid flows in either direction. These are spring-loaded flow shut-off valves, which will only close when the flow through the valve exceeds a predetermined closing flow rate in the direction marked on the valve. Each valve has a closing flow rate based on specified conditions. Our 2000 series Excess Flow valves can be used for several types of fluids and processes including LP gas, butane, anhydrous ammonia, anhydrous chlorine, nitrogen air, water, and others. Excess Flow valves are available in a wide variety of pressure classes, materials, flange designs and end connections. All valves are tested in our certified flow laboratory. Test certificates and performance graphs are provided by our state-of-the-art data-acquisition system, Total Valve Live.

To schedule a brief presentation that can be held at your location or via Webinar, please contact us at Sales@totalvalve.com.

Series 2100

Between Flanges for Bypass Resetting

Series 2400

Tank Applications

Series 2600

Externally Adjustable – Fire Safe API 6F Rated

Note: All valves are available by different pressure classes. We will custom design and manufacture an excess flow valve to meet customer and federal requirements. Dimensions shown are for standard design and are subject to change without notice. See our product catalog for individual valve specifications.

Wafer

2100 Series

The 2100 is designed to easily insert into piping between ASME/ANSI flanges. These valves are durable and provide generous flow paths. Closing flow rates are factory preset to customer specifications.

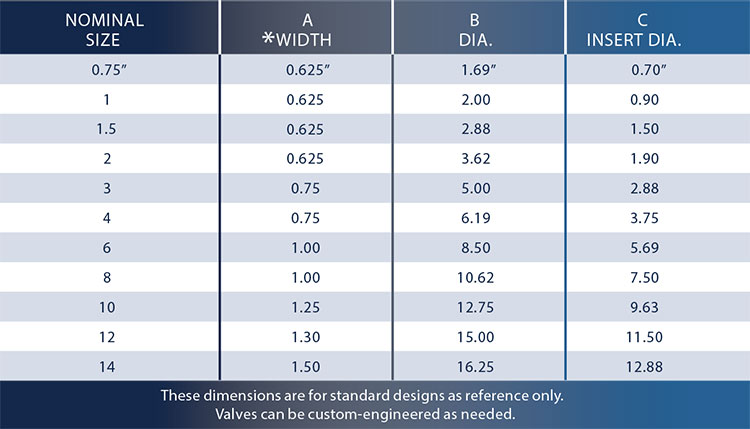

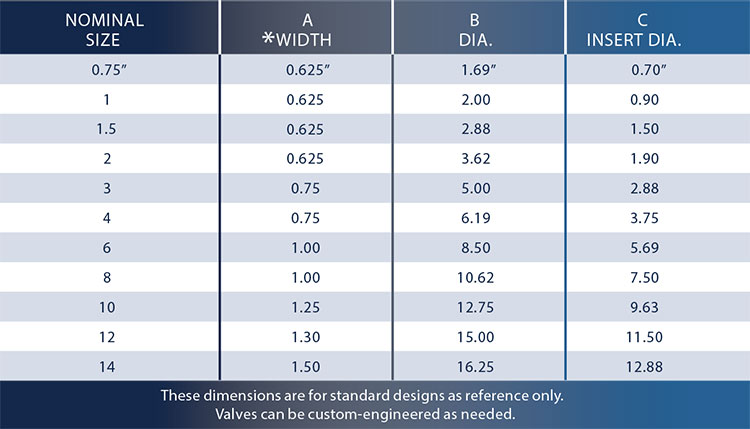

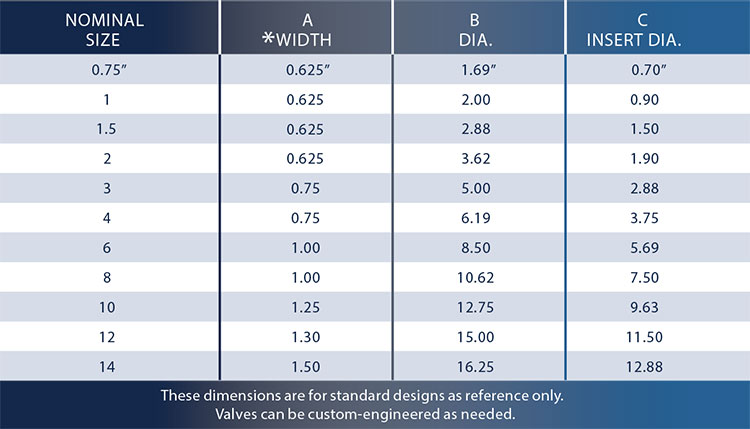

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches. Closing flow rates are factory preset per customer requirements.

Product Information

Excess Flow Valve Quote/Inquiry Form

Model 2105

The 2105 is designed to easily insert into piping between ASME/ANSI flanges. This is the high flow version of the 2100 model to reduce pressure drop across the valve. Closing flow rates are factory preset to customer specifications.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches.

Product Information

Excess Flow Valve Quote/Inquiry Form

Model 2106

The 2106 is designed to easily insert into piping between ASME/ANSI flanges. This valve operates similar to a check valve in one direction to open up as the flow increases through the valve and shut-off in the other direction when excess flow occurs. This valve is capable of lower shut off flows than the model 2105. Closing flow rates are factory preset to customer specifications.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches.

Product Information

Excess Flow Valve Quote/Inquiry Form

Double Flanged

2120 Series

The 2120 Series Excess Flow Valves are designed and manufactured with standard ASME/ANSI flanged ends to be used in liquid, gas, and vapor service. The 2120 Series comes in a variety of pressure classes, sizes, and by-pass options. These valves are heavily constructed to withstand years of service, and continue to be Total Valve's #1 selling valve due to its versatility and reliability.

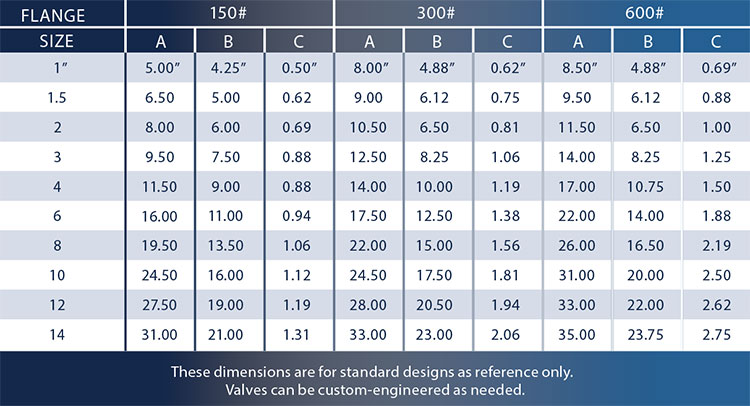

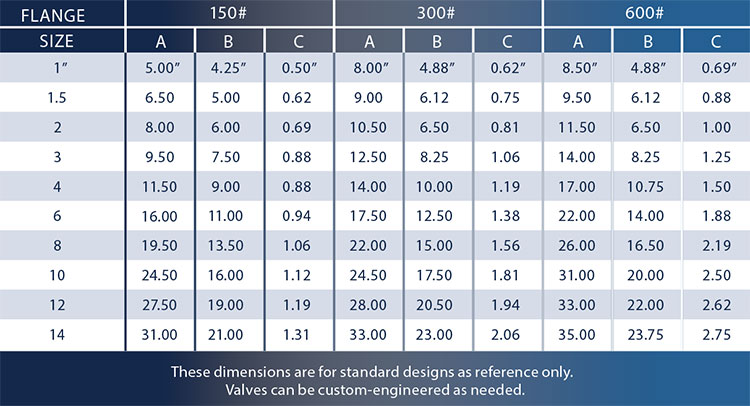

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches. Closing flow rates are factory preset per customer requirements.

Product Information

Excess Flow Valve Quote/Inquiry Form

Model 2125

The 2125 Series Excess Flow Valves are designed for use in liquid, gas or vapor service. The 2125 comes standard with 150#, 300#, or 600# ANSI/ASME class flanges. The 2125 is a high flow version of the model 2120 to allow for substantially lower pressure drops. Options for this model include No Reset (standard), automatic reset, manual bypass, and other options can be added. These valves are heavily constructed to withstand years of service. This model allows for an increase in flow rates over the normal valves without increasing line size.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches. Closing flow rates are factory preset per customer requirements.

Product Information

Excess Flow Valve Quote/Inquiry Form

Model 2600

The 2600 Series are Externally Adjustable Excess Flow Valves. The top entry design enables ease of adjustment and maintenance. Various sizes are used in facilities from laboratories to refineries, chemical processing plants, semiconductor industry, pharmaceutical, biotech and food plants.

Unique features include an external adjustment for changing the shut-off flow. Adjustments can be made externally by turning a threaded member extending through the valve, which causes a retainer to move laterally within the chamber. The threshold flow rate of the valve can be set. Optional features include soft seats, external bypasses, actuators, and other items. Valves are Fire Safe: Certified to API 6FA and can meet NACE standards.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches.

Product Information

Excess Flow Valve Quote/Inquiry Form

Threaded / Welded

2130 Series

The 2130 Series Excess Flow Valves are designed for use in liquid, gas or vapor service to stop the flow in the event of a sudden flow change. The 2130 Series have male NPT connections on the inlet side and female NPT connections on the outlet side. These valves offer excellent flow rates and can be used in many different applications. Internal components are also available in ceramic. Wrench flats are included.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches.

Product Information

Excess Flow Valve Quote/Inquiry Form

Model 2140

The 2140 Series Excess Flow Valves have female NPT connections on the inlet side and male NPT connections on the outlet side. The 2140 Series is designed for use in liquid, gas or vapor service to stop flow in the event of a sudden flow rate change. Different size end connections are available.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches. Closing flow rates are factory preset per customer requirements.

Product Information

Excess Flow Valve Quote/Inquiry Form

Model 2150/2180

The 2150 Series Excess Flow Valves have female NPT connections on the inlet side and female NPT connections on the outlet side. The 2150 Series is designed for use in liquid or vapor service to stop the flow in the event of a sudden flow rate change. These valves offer excellent flow rates and can be used in many different applications. Options include an external manual bypass that allows for faster equalization across the poppet. Can be used with standard poppet or soft seat with no weep hole.

The 2180 Series Excess Flow Valves are designed for use in liquid, gas, vapor or mixed service. It can be either a single or multiple rate, different rate settings can be selected while performing field service. The 2180 Series has female NPT connections on both the inlet and outlet sides. Options include an external manual bypass that allows for faster equalization across the poppet. Can be used with standard poppet or soft seat with no weep hole.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches. Closing flow rates are factory preset per customer requirements.

Excess Flow Valve Quote/Inquiry Form

Model 2160

The 2160 Series Excess Flow Valves have male NPT connections on the inlet side and male NPT connections on the outlet side. The 2160 Series is designed for use in liquid, gas or vapor service to stop flow in the event of a sudden flow rate change.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches. Closing flow rates are factory preset per customer requirements.

Product Information

Excess Flow Valve Quote/Inquiry Form

Socket Weld

Model 2170

2170 Series Excess Flow Valves is the socket weld version of the Model 2150. The 2170 Series is designed for use in liquid, gas or vapor service to stop flow in the event of a sudden flow rate change.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches. Closing flow rates are factory preset per customer requirements.

Excess Flow Valve Quote/Inquiry Form

Model 2400

2400 Excess Flow valves are designed to provide internal shut-off for tanks of all sizes. Applications include LPG, Butane to other chemicals. The Valve seat and shut-off is internal to the tank to meet various industry compliance requirements. (NFPA 58, etc.) Optional features include external handle with locking device to shut or open the valve for start-up and plant maintenance, automatic reset versions, and other options.

See tables below for dimensions of common sizes.

*Custom CVs upon request.

Valves are custom-engineered and the dimensions provided above are for reference only. Sizes displayed are in inches.