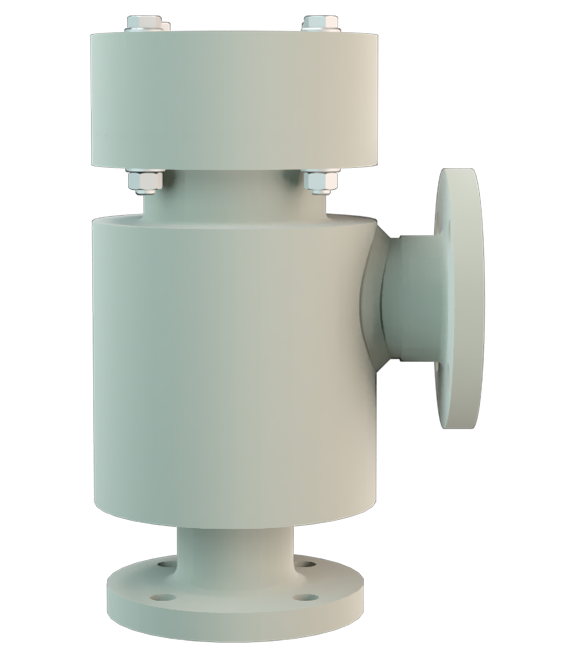

R/KSM

- 10% technology for minimum pressure increase up to full lift

- extreme tightness, resulting in lowest possible product losses and reduced environmental pollution

- based on 10% technology, set pressure is close to opening pressure for optimum pressure maintenance in the system as compared to conventional 40% or 100% technology

- can be used as pressure or vacuum relief valve

- compact, space-saving right-angle design

- high flow capacity reduces costs through the use of smaller valves

- non-corrosive

- weight reduction in comparison to steel/stainless steel

- high surface quality

- different plastics can easily be combined

- maintenance-friendly design

The PROTEGO® in-line valve R/KSM is a state-of-the-art pressure or vacuum relief valve in a right angle design made out of high-grade synthetic material. Typically, the valve is installed in the in-breathing or out-breathing lines of tanks, vessels, and process equipment to protect against unallowable overpressure or underpressure. The valve prevents emission losses almost up to the set pressure and prevents unacceptable product entry. The valve is a perfect solution for corrosive, polymerizing, or sticky substances.

The device will start to open as soon as the set pressure is reached and only requires 10% overpressure to full lift. Continuous investments in and a commitment to research and development have allowed PROTEGO® to develop a low pressure valve which has the same opening characteristic as a high pressure safety relief valve. This "full lift type" technology allows the valve to be set at just 10% below the maximum allowable working pressure or vacuum (MAWP or MAWV) of the tank and still safely vent the required mass flow.

The opening characteristic for pressure and vacuum side is the same. Due to our highly developed manufacturing technology, the tank pressure is maintained up to the set pressure with a tightness that is far above to the conventional standard. This feature is ensured by special valve seats made of high quality synthetic material or PTFE. After the overpressure is released or the vacuum is balanced, the valve re-seats and provides a tight seal.

The optimized fluid dynamic design of the valve body and valve pallet is a result of many years of research, resulting in stable operation of the valve pallet, optimized performance, and reduced product losses.