Industrial In-line Valve Repair and Maintenance

Industrial In-line Valve Repair and Maintenance | Tulsa, Oklahoma

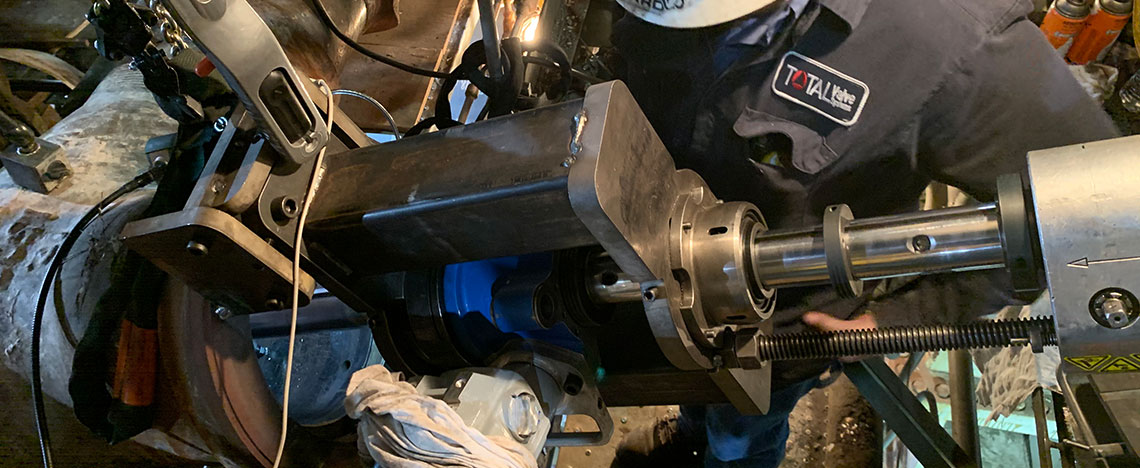

Total Valve Systems' full service in-line valve repair services include welding, machining and millwright services under one roof. This allows us to offer top quality inline valve repair and maintenance services in accordanance with ASME section 1 and B31.1.

Our welders, machinists and personnel use specialty and proprietary equipment to offer top notch in-line valve repair for a variety of inline valve for all major manufacturers. Repairs of code boundary valves are performed in accordance with the guidelines of ASME Section I as well as National Board Inspection Code including jurisdictional requirements.

Our highly trained techincians are some of the most experienced in the field. Total Valve can offer line valve repair from any manufacturer, either in the field or at one of our locations.

Whether you are needing globe, check, gate, safety or control valve repair, we can handle complete line valve repair services on ALL types of valves. Every valve repaired by Total Valve Systems will be repaired and tested to both the manufacturer's specifications and the customer's needs. Total Valve will warranty our work on both normal service and emergency line valve repair. Pick-up and delivery service is available.

Industrial In-Line Valve Repair and Maintenance Includes:

- Stems/Spindles

- Seats/Trim/Diffusers

- Main Discs

- Caps

- Cross-heads

- Seals

- Bushings

- Nuts/Bolts

- Strainers

- Pilot Plug

- Pressure Seal Head

- Pressure Seal Ring

- Balance Chamber

- Control Valve

- Inlet Valve

- Main Steam Stop Valve

- Equalizer Valve

- Intercept Valve

- Blow-down Valve

- Governor Valve

- Ventilator Valve

- Throttle Valve

- Combined Control Stop Valve

- Combined Reheat Stop Valve

- Governor / Control Valves Throttle Valves

- Combination Valves

- Butterfly Valves

- Apply special processes / HVOF to increase wear resistance

- Processes include: Nitriding, Malcomizing, Chrome Carbiding

- Provide complete data sheets & final report for project

- Safe pick-up & delivery of components

- Valve Inserts

- Sub Assembly

- Throttle Mods, upgrades

- Steam Blow- Off Valves and Blowdown Valves

- Power Boiler Trim Valves

- Power Industry Butterfly Valves

- By-Pass Systems

- Free flow and other types of check valves

- Control Valves and Valve Actuators

- Steam Desuperheaters, supercritical service

- Power Pressure

Management Valves:

- Boiler Safety Valves, Pressure Relief Valves

- Pilot Operated Pressure Relief Valves

- Safety Selector Valves

- Tank Protection

- Instrumentation Products for power plants

- Slurry Isolation and Knife Gate Valves

- (FGD) Fluid Gas Desulfurizer slurry service knife gate valves

- SEVERE Service Ball Valves

- Steam Traps-steam condensation traps

- Vents and Drains

- Boiler Feed Water Check Valves, Steam Extraction Check Valves

- Cold Reheat Isolation Valves

- High-Pressure Ash Water Valves

- Fuel Gas Isolation Valves, Pilot Gas Valves

- Solar salt and HTF valves for solar energy power

- Cold reheat steam isolation valves

- High-pressure ash water valves on power plants

- Condensate Booster Pump Isolation valves

- Burner Gas Isolation valves, Fuel Oil, 600 # steam service valve

- Bonnet bore refurbishment

- Butt Weld Modifications

- Seat removal and replacement

- Deep bore welding for valve seats

- Stud extraction and hole refurbishment

- ASME Section IX weld repairs

- Flange face resurfacing (including elliptical)

- Field machining processes for all sealing surfaces and fit areas

- Manual and Automatic hard facing of seats and discs