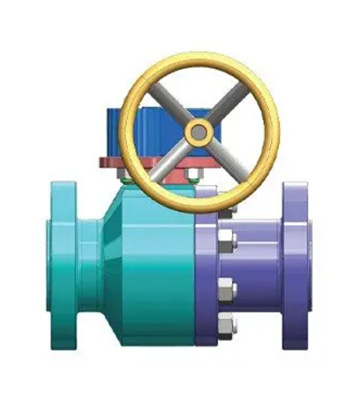

Floating Ball Valves

WOM’s Floating Ball Valves provide the user with an exceedingly reliable and proven design offering maximum sealing against leaks. WOM’s Floating Ball Valves have separate ball and stem design with a free floating ball preloaded between the seats during assembly.

When pressure enters the valve from the upstream side, the ball stem slot allows the ball to float freely under pressure moving from its axis to seal on the downstream side, resulting in a pressure assisted seal. The stem remains in the valve axis, enhancing stem seal performance for a tight seal joint.

WOM Floating Ball Valves are suitable for the following applications:

- Oil and gas service with NACE and Non-Nace based material selections.

- Pharmaceutical and Chemical Industry based material selection.

- Standard temperature range of -20ËšF to 250ËšF

- Temperature range of -40ËšF to 250ËšF can be supplied on demand.